Product Description

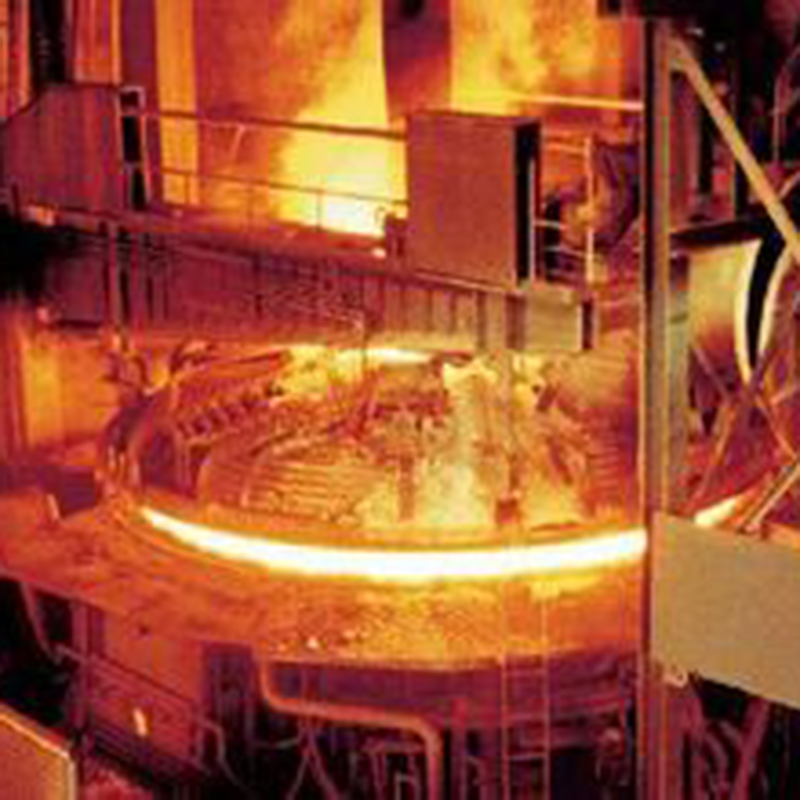

Wollastonite has been widely recognized as an excellent additive for continuous casting mold powders and tundish powders in the steel industry. Its stable chemical properties and unique characteristics make it an invaluable component in various steel production processes.

One of the key benefits of using wollastonite in continuous casting mold powders and tundish powders is its ability to lower the melting point. By incorporating wollastonite into the powders, the overall melting point of the mixture is effectively reduced. This is particularly advantageous in the steel industry, where precise temperature control is crucial for achieving optimal casting conditions.

Additionally, wollastonite plays a vital role in the prevention of re-oxidation. During the steelmaking process, the presence of oxygen can lead to undesirable oxidation reactions. Wollastonite has the ability to absorb oxygen, thereby minimizing the risk of re-oxidation and ensuring the production of high-quality steel products.

Moreover, wollastonite is highly effective in absorbing non-metallic inclusions. Non-metallic inclusions, such as oxides, sulfides, and silicates, can negatively impact the mechanical properties of steel. By incorporating wollastonite into the powders, these inclusions are selectively absorbed, resulting in steel products with improved purity and enhanced mechanical performance.

Another significant advantage of using wollastonite is its ability to facilitate uniform heat transfer during the casting process. Wollastonite acts as a thermal conductor, enabling the efficient transfer of heat from the molten metal to the mold or tundish walls. This uniform heat distribution helps to prevent localized hotspots and ensures consistent cooling, resulting in the production of defect-free steel products.

Furthermore, the presence of wollastonite in continuous casting mold powders and tundish powders helps reduce nozzle blockages. Nozzle blockages can occur due to the accumulation of impurities or solidified slag particles, leading to interruptions in the casting process. Wollastonite, with its fine particle size and excellent flowability, prevents the formation of blockages and ensures a smooth and continuous flow of molten metal.

Lastly, the inclusion of wollastonite brings a significant amount of calcium oxide (CaO) to the steelmaking process. CaO is an essential compound that promotes the removal of impurities and assists in the formation of slag. By introducing wollastonite, the overall CaO content is increased, enhancing the effectiveness of the steelmaking process and resulting in steel products of higher purity and refined mechanical properties.

In summary, wollastonite’s stable chemical properties and diverse range of benefits have made it an indispensable additive in the steel industry. Its role in lowering the melting point, preventing re-oxidation, absorbing non-metallic inclusions, facilitating uniform heat transfer, reducing nozzle blockages, and enhancing the presence of CaO has greatly contributed to the production of high-quality steel products. Industries continue to rely on the unique properties of wollastonite to optimize their steel production processes and improve overall efficiency.